How IVR Systems for Manufacturing Improve Efficiency and Enhance CX

by Anastasia Micic | Published On April 15, 2025

Have you ever called a manufacturing company to check in on the status of an order, or ask a billing question, only to be greeted by an automated system guiding you through a list of options? If so, you’ve seen an IVR system for manufacturing in action.

IVR (Interactive Voice Response) systems have been a core part of the contact center landscape for years now, helping companies to cut costs, streamline routing tasks, and improve efficiency. As manufacturing companies continue to explore innovative ways of automating tasks, and improving customer experiences, cutting-edge IVR technologies are becoming increasingly important.

They’re helping organizations to streamline internal operations, manage routine tasks, provide real-time updates to consumers, and elevate customer satisfaction rates. Even in the age of AI-powered automation, analysts like McKinsey say IVR systems are still crucial to contact center success.

Here’s your guide to how you can use powerful IVR solutions to revolutionize your manufacturing contact center.

What is IVR in Manufacturing?

IVR stands for “Interactive Voice Response” – a technology that enables phone-based self-service experiences for customers by allowing them to navigate a menu of options with either keypad inputs, or voice commands. When you call a company and navigate through menu options by speaking or pressing numbers, you're engaging with an IVR system.

IVR systems automate call handling processes, allowing callers to access information, connect to a specific department, or even complete tasks (like making a payment), without human intervention.

In the manufacturing sector, IVR systems serve various purposes. They can handle routine order placements; allow callers to check stock levels, delivery schedules, or business’ operating hours; and even share valuable insights with customers into technical issues or faults.

The main purpose of an IVR system is to streamline communications. It ensures information can be shared quickly, effectively, and autonomously with callers, reducing operational bottlenecks, improving efficiency, and enhancing customer experiences.

The Key Benefits of IVR for Manufacturing

In every industry, IVR systems help companies to boost customer satisfaction rates, reduce operational costs, and improve team productivity. They also ensure companies can adapt to the changing priorities of today’s customers. After all, around 81% of customers say they prefer to use self-service tools like IVR systems when they’re interacting with brands.

For manufacturing companies, IVR systems deliver:

Improved Customer Service

85% of manufacturing companies believe they need to “digitally transform” and invest more heavily in customer service to stay competitive. IVR systems ensure businesses can adapt to changing customer priorities, giving callers access to intuitive and adjustable menu options.

IVR systems can provide 24/7 automated responses to common inquiries, ensuring customers receive immediate assistance regardless of the time. This means they can reduce waiting times for customers and even minimize the number of callers that need to wait in a queue for human support.

Enhanced Order and Shipment Tracking

In a manufacturing contact center, many agents spend a significant amount of time answering repetitive queries about shipments and orders. With an IVR, customers can check the status of their order instantly, without having to speak directly to an agent.

This empowers customers to get answers faster, while also reducing the workload on customer service representatives. Employees end up with more time to focus on other valuable tasks, like building relationships with clients, or handling complex issues.

Efficient Internal Communication

IVR systems in manufacturing don’t just streamline communications with customers. They can help align departments and automate workflows for teams too. For example, employees can use IVR to report equipment issues, request maintenance, or receive updates on company policies.

Some manufacturing companies even use IVR systems to streamline communications with suppliers, logistics companies, and other partners, keeping systems and processes running smoothly.

Reduced Operational Costs

Modern contact center solutions, like IVR systems, are often incredibly effective at helping companies to minimize operational costs. For instance, by automating repetitive customer service tasks, IVR systems free up human resources to focus on more complex and value-added activities.

Additionally, because IVR systems can help to improve routing processes and minimize call transfers, they make teams more efficient, ensuring less time is wasted in day-to-day workflows.

Faster Issue Resolution

Manufacturing IVR systems can both immediately answer common questions and direct calls to the appropriate department or agent based on a caller’s needs. This ensures that issues are addressed a lot faster in the contact center, reducing waiting times and improving overall efficiency.

When issues are resolved faster, customer satisfaction rates increase and contact center agents complete more tasks in less time, improving overall performance.

Use Cases for IVR in Manufacturing

Interactive Voice Response systems are versatile solutions for manufacturing companies, giving organizations unique opportunities to streamline communications and improve experiences in various ways. Some major use cases for IVR tools include:

- Customer Support Automation: Manufacturers often receive numerous inquiries about orders and technical support. Implementing IVR systems enables customers to access self-service options, so they can check order statuses or troubleshoot issues without a human representative. This improves customer satisfaction because consumers can solve issues faster and reduces the workload on support staff.

- Supplier and Vendor Management: Maintaining an efficient supply chain is crucial in manufacturing. IVR systems can automate communications with suppliers and vendors, providing real-time updates on inventory levels, delivery schedules, and potential supply chain disruptions. For instance, a supplier can call into the IVR system to receive automated information about stock requirements or delivery confirmations, ensuring timely responses and reducing manual intervention.

- Employee Communication: Managing a large workforce involves tracking attendance, scheduling shifts, and addressing human resources (HR) inquiries. IVR systems streamline these processes by allowing employees to report absences, receive schedule updates, and get answers to common HR questions through automated prompts. This reduces administrative burdens and ensures that employees have access to necessary information at any time.

- Equipment Maintenance Requests: Timely maintenance of machinery is vital to prevent production downtime. IVR systems facilitate automated ticketing for machine repairs and downtime reporting. Employees can quickly report equipment issues through the IVR, which then alerts the maintenance team for prompt action. This can help manufacturing teams reduce delays and minimize risks.

- Multi-Language Support: For manufacturers operating globally, IVR systems – particularly intelligent IVR solutions – are excellent for delivering support to customers in their preferred language. The right IVR system can help organizations scale their services across geographies, increasing revenue, unlocking new opportunities.

How to Implement an Effective IVR System in Manufacturing

Modern IVR systems are becoming increasingly valuable to organizations in the manufacturing industry, with more advanced tools for scripting, automation, and even AI-driven interactions. Designing and deploying the best IVR solution, however, requires a careful approach.

Step 1: Identify Business Needs

First, decide how you’re going to be using your IVR system. Are you just using it for customer self-service, or to support employees and internal collaboration too? Look for opportunities by analyzing call logs and customer feedback. For instance, if a significant number of calls pertain to order statuses or technical support, you might design your IVR system with a focus on tackling these issues.

Step 2: Design a User-Friendly IVR Menu

No-one wants to navigate a complicated or confusing IVR menu. To create a seamless customer experience, focus on simplicity. Limit the number of options you give callers to avoid overwhelming them (for instance, keep choices to five or fewer per level). Use clear, concise language and avoid industry jargon. For example, instead of saying, "For procurement inquiries, press 1," opt for, "To check your order status, press 1." Make it easy to navigate the system effortlessly.

Step 3: Integrate with Existing Systems

Integrations are powerful in any contact center, particularly when it comes to maximizing the impact of your IVR system. Make sure you can connect your IVR technology with your Enterprise Resource Planning (ERP), Customer Relationship Management (CRM), and supply chain management software.

This connectivity allows the IVR to access real-time data, enabling functionalities like order tracking, inventory checks, and customer information retrieval. For instance, integrating IVR with CRM can personalize interactions by addressing customers by name and referencing their purchase history, enhancing the overall experience.

Step 4: Use AI and Speech Recognition

Incorporating Artificial Intelligence (AI) and speech recognition technologies into your IVR system is a great way to enhance its performance and improve the customer experience. Rather than having to press buttons and follow rigid prompts, customers will be able to interact with the IVR system using natural language – streamlining the process.

For example, a customer can say, "I want to check my order status," and the system will process this request accurately. This advancement can even help to reduce the number of customers that simply give up on trying to navigate your IVR and ask to speak directly to a representative.

Step 5: Monitor and Optimize

No crucial technology in your manufacturing contact center should be implemented and then simply forgotten about. Continuous monitoring and optimization are vital for maintaining an effective IVR system. Regularly analyze call data to identify drop-off points or frequent misrouting issues.

Gather customer feedback to understand pain points. Use this information to refine menu options, update scripts, or introduce new features. For instance, if data shows that many callers are confused by a particular menu option, rephrase it to improve navigation.

Choosing the Right IVR Solution for Manufacturing

At this point, you might be keen to invest in your own IVR solution, but you could be wondering how to go about exploring your options. For the best return on your investment, we recommend focusing on three key things: features, deployment options, and security.

Key Features to Look for in an IVR System

- Scalability: Ensure the system can grow with your business, accommodating increased call volumes without compromising performance.

- Integration Capabilities: The IVR should seamlessly integrate with existing systems like Customer Relationship Management (CRM) and Enterprise Resource Planning (ERP) to provide a unified workflow.

- User-Friendly Interface: A straightforward interface allows for easy updates to call flows and prompts, reducing dependency on specialized IT staff.

- Advanced Call Routing: Features like skills-based routing direct callers to the most qualified agents, enhancing customer satisfaction.

- Analytics and Reporting: Access to detailed call analytics helps in monitoring performance and identifying areas for improvement.

Cloud-Based vs. On-Premises IVR Solutions

Do you need your system to be agile and cloud-based or installed on-premises? An on-premises IVR could be ideal if you want absolute control over data and customization options (particularly if you’re exposed to strict data security guidelines).

However, a cloud-based contact center can give you greater flexibility and scalability, with fewer upfront costs. Cloud-based IVR systems don’t require extensive hardware investments, and they allow you to adjust resources and features on-demand.

Security and Compliance Considerations

Manufacturing companies often deal with a lot of sensitive data, so make sure you have the right security strategies in place. Invest in IVR systems that deliver:

- Data Encryption: Both in transit (moving across networks) and at rest(stored in a database), data should be encrypted to prevent unauthorized access.

- Compliance with Standards: Ensure the IVR provider complies with relevant industry standards and regulations, such as GDPR or HIPAA, depending on your operational region.

- Access Controls: Implement strict access controls to limit who can modify the IVR system or access sensitive data.

- Regular Audits: Conduct periodic security audits to identify and address vulnerabilities promptly.

- Disaster Recovery Plans: Verify that the provider has robust disaster recovery protocols to ensure business continuity in case of system failures.

The Future of IVR in Manufacturing

IVR systems might not be new concepts in the contact center space – or even the manufacturing industry – but the capabilities of these tools are constantly evolving. Today, for instance, many modern IVR solutions feature artificial intelligence, natural language processing capabilities, and intuitive voicebots that can help enhance the self-service experience for customers.

Modern IVR systems designed specifically for manufacturing companies are also adapting to sector-specific trends. For instance, IVR systems connected with IoT devices in the “Industry 4.0” and smart factories era can provide real-time insights into machinery performance, enhance quality control, and even enable predictive maintenance strategies.

Going forward, evolving IVR solutions will empower companies of all sizes to unlock new levels of automation, enhance team collaboration, and strengthen customer experiences like never before.

IVR for Manufacturing: Revolutionizing Customer Service

IVR systems remain a crucial resource for manufacturing contact centers. They’re helping companies streamline communications, automate routine tasks, and improve customer service at scale. As these technologies become more advanced and intuitive, they’ll only continue to make manufacturing organizations more efficient, productive, and profitable.

If you’re ready to take your approach to customer service in the manufacturing space to the next level, now could be the perfect time to start experimenting with cutting-edge IVR systems.

Learn how smart IVR solutions from ComputerTalk can optimize your business processes, reduce costs, and enhance customer loyalty in our Smart IVR guide.

More from our blog

Cloud Contact Center Solution with Tethr and Community WFM Integration

Cloud Contact Center Solution with Tethr and Community WFM Integration

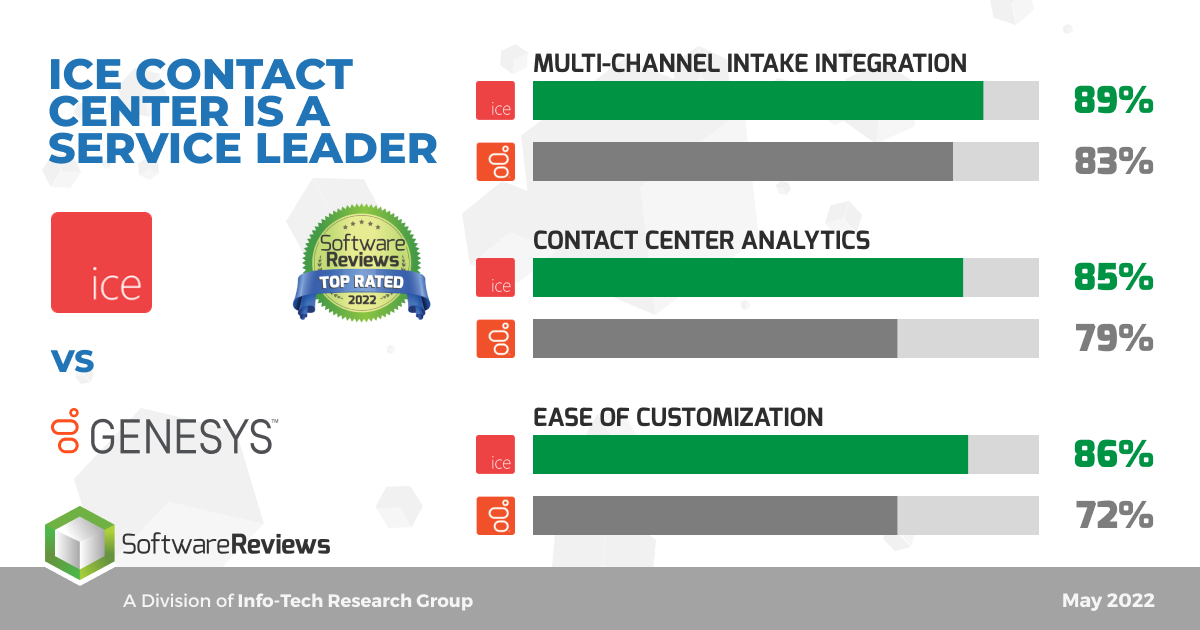

ComputerTalk is pleased to announce that we have been scored as a leader against Genesys in the InfoTech Research Group’s SoftwareReviews.

ComputerTalk is pleased to announce that we have been scored as a leader against Genesys in the InfoTech Research Group’s SoftwareReviews.

Discover how ComputerTalk’s ice Contact Center evolved alongside Microsoft—from LCS and OCS to Lync, Skype for Business, and Microsoft Teams.

Discover how ComputerTalk’s ice Contact Center evolved alongside Microsoft—from LCS and OCS to Lync, Skype for Business, and Microsoft Teams.